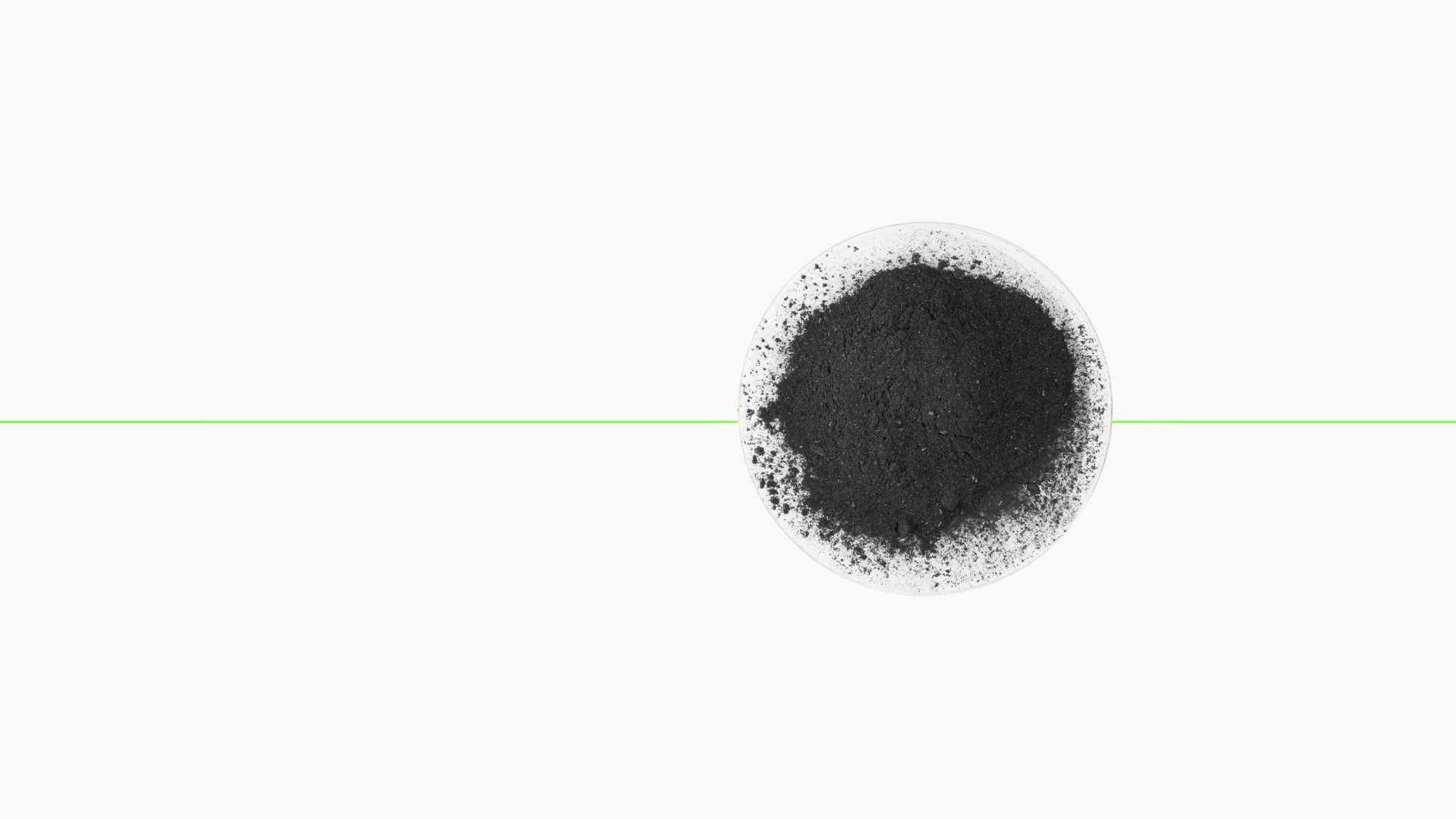

The quality and durability of tyres is highly affected by carbon black, especially the tyre tread, which is subjected to abrasion and tearing. Our extensive range of Carbon Black solutions help tyre manufactures to meet different types of tyre requirements and applications to improve tyre life, provides better grip, and increases fuel efficiency.

Apart from tyres, our products are designed for industrial rubber products and automobile parts. Our Carbon Black grades exceed the global standards for carbon black set by the American

Society for Testing and Materials (ASTM). We work with our customers for continuous improvement, which helps manufacturers meet current and future market demands. At Epsilon Carbon, we are using our vast experience in the field of coal tar derivatives to produce high grade coal tar-based feed stock to produce superior quality carbon black. Our high carbon index and low sulphur coal tar-based feed stock helps in sustainable product and imparts lower carbon footprint while manufacturing.

Our Products

Explore our range of carbon black components

The hard grades of Carbon Black, also called ‘Tread Black’ is commonly used as the most cost-effective rubber reinforcing agent in tyre components such as treads.

N220

Used in tread compounds of tyres for trucks and passenger cards, N220 grade offers high tensile strength. Its high abrasion properties make this grade the preferred choice in rubber products such as high strength conveyor belts, industrial rubber articles etc.

Product DatasheetN234

An improved process high structure carbon black, N234 has excellent wear and extrusion properties. Used in all elastomers, especially DBR/BR blends for treads and tread rubbers.

Product DatasheetN326

Used in mechanical goods, tyre carcasses, belts, and off-road treads due to its low structure, high reinforcement properties, high tensile strength and tear and chipping resistance.

Product DatasheetN330

Provides good abrasion resistance as well as high resilience, easy processing, good tensile strength, and tear resistance. The N330 is suited to a wide range of applications in both tyres and mechanical goods.

Product DatasheetN339

Has excellent wear and extrusion properties characteristic of improved process high structure carbon blacks. It is suited to passenger treads, tread rubber, and mechanical goods.

Product DatasheetN375

Mainly used in tread compounds of passenger, truck, and cross-country tyres. It is also an excellent choice for the coating compounds of conveyor belts.

Product DatasheetRho3

Used in rubber applications that require very low polycyclic aromatic hydrocarbons (PAH) content and follows ASTM N300 series carbon. It has excellent extrusion characteristics, and the ease of dispersion makes it factory friendly. It is recommended for industrial rubber product applications and master batch, including conveyor belts, solid tyres and other products requiring moderate abrasion resistance.

N347

It is a high structure and low particle size carbon black, which gives good resistance to cuts and chips. N347 is well suited for tyre treads that require medium to good wear resistance with low hysteresis.

N134

upcoming grades by Mar 2024

N121

upcoming grades by Mar 2024

The soft grades Black, Lorem ipsum dolor sit amet, consectetur

N550

Imparts medium abrasion resistance, high tensile strength, low shrinkage and die swell. It also provides fast, smooth extrusions and relatively high resilience. It is used in tyre carcasses, cushion gums, tubing, cable jacketing, plastic conduit compounds, etc. It's also used in extruded goods that require excellent dimensional stability.

Product DatasheetN660

It is an excellent all-purpose Black, that can be used in tyre carcasses, sidewalls, and mechanical goods. With moderately reinforcing properties, N660 provides good reinforcement, low heat generation, and smooth processing to all elastomers.

Product DatasheetRho5

Carbon black has a very high structure and low surface area. It combines good cleanliness with a unique morphology and is especially developed for extruded rubber applications like weather stripping, hoses, and profiles.

Rho6

Carbon black gives very smooth surfaces and good elasticity in extruded profiles making it an excellent choice for low-viscosity and low hardness applications. It has a very low surface area with a medium-high structure level. This special carbon black morphology allows an excellent dispersion level with a relatively high carbon black loading. It provides improved performance for a wide range of hose, extrusion, and moulded applications.

N772

It is semi-reinforce furnace carbon black used in a wide range of industrial rubber product applications, particularly in applications requiring low modulus, low compression set, good resilience, and high carbon black loadings.

N774

A moderately reinforcing grade, N774 has excellent dynamic properties. It has high resilience, low hysteresis and allows high loadings. It is used in extruded goods, belts and hoses, molded goods, and plastic colour concentrates.

Product DatasheetIndustry Applications

Fueling industries across the spectrum

Green Supply

Chain Management

As a result of our efforts towards greening of raw materials; integration of green technologies; circularity of resources and materials; and, reducing emissions from our logistics operations, our products have lower embodied Greenhouse Gas (GHG) as compared to conventional products.

Product Stewardship

Sustainable product innovation is one of our key strategic growth pillars and is driven from the highest levels within the organizational structure to design products that deliver environmental benefits to consumers

Quality Management

We mainly target our raw material suppliers for this activity. The selected suppliers are encouraged to submit data in line with Quality Management System (QMS) requirements.